Explore how hydraulic cylinders enhance construction machinery efficiency and performance. Understand their critical role and impact.

Hydraulic cylinders play a pivotal role in construction machinery, providing the robust mechanical force necessary to operate heavy equipment efficiently. These workhorses within hydraulic systems take the power of pressurized hydraulic fluid and transform it into controlled linear motion. This drives the core operations of various construction devices – the lifting, pushing, and digging that get the job done.

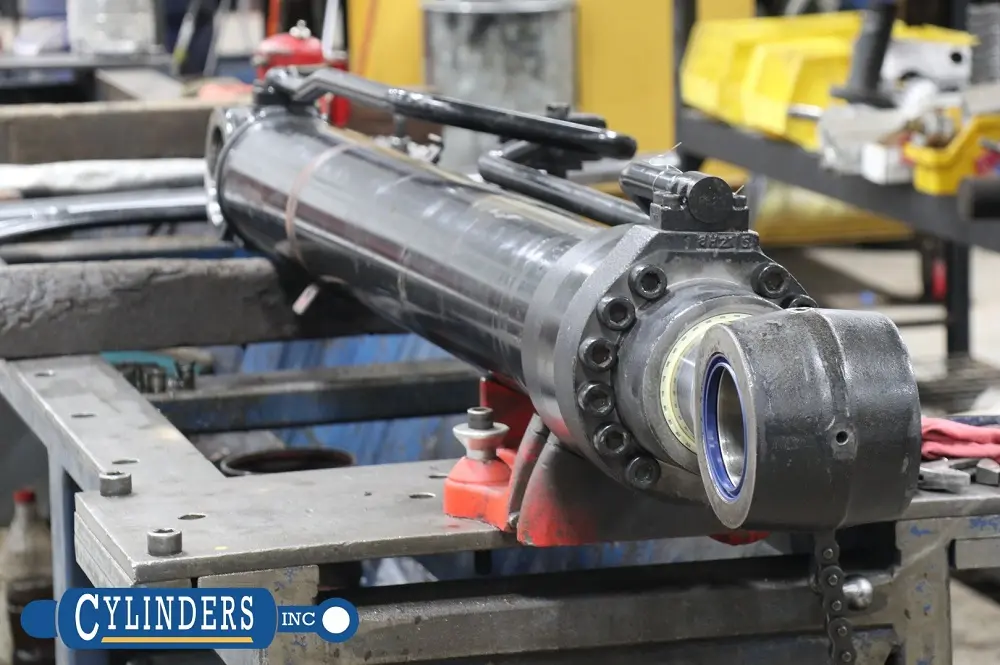

In case you are experiencing downtimes due to hydraulic cylinder failure of one or several of your construction machines in Chicago, we at Cylinders, Inc. can help. As the top experts in hydraulic cylinder repair, we’re dedicated to getting your equipment back up and running quickly.

Ever wonder how we moved from hand tools to towering skyscrapers? The answer lies in the power of hydraulics! It might surprise you that the seeds of this technology were planted way back in 1882 with the first clunky, steam-powered excavator.

Sure, it was rough around the edges, but it proved the concept. Then, in 1897, the first all-hydraulic excavator revolutionized construction – smoother movement and less muscle power required from the operator.

But the real boom came in the 1960s when hydraulics started replacing cables on construction equipment, from dozers to backhoes. This gave us the power and precision to reshape the world on a whole new scale.

Today, advanced hydraulic technology is what makes those seemingly impossible construction deadlines a reality.

Hydraulic cylinders are the backbone of this revolution. At their core lies the piston rod, the key to turning hydraulic power into the real-world work of lifting, pushing, and digging.

These cylinders are carefully constructed with several important parts: the cylinder barrel that houses the piston, the piston rod, and the hydraulic cylinder seals that prevent leaks and keep the pressurized fluid where it belongs.

Understanding what is a hydraulic cylinder is essential for anyone working with heavy machinery, especially in the construction industry.

Construction sites are demanding environments, and the machinery needs to match that toughness. Hydraulic cylinders, the powerhouses behind the movement of heavy equipment, come in several specialized types to meet the industry’s varied needs.

Here’s a look at some of the most common:

The right hydraulic cylinder is carefully matched to specific criteria – load capacity, environmental resilience, and space constraints – to guarantee optimal performance in diverse construction tasks.

Learn more with our guide on the types of hydraulic cylinders.

Hydraulic systems are the powerhouse behind much of today’s construction equipment. They offer advantages in power, precision, and durability that enhance the capabilities and safety of these machines.

Let’s look at some specific examples:

Integrating hydraulic systems in construction equipment brings significant benefits:

Hydraulic cylinders are the backbone of construction machinery, but even these powerful components face challenges that can affect their performance and lifespan. One persistent issue is fluid leaks, which can hinder efficiency and potentially lead to equipment failure. Other common challenges include wear and tear on seals and bearings, corrosion of exposed parts, and contamination of the hydraulic fluid.

Proactive maintenance is essential to address these issues.

Here are key maintenance tips:

By following these maintenance practices, you’ll help ensure your hydraulic cylinders continue to deliver reliable performance, minimizing costly downtime and keeping your construction projects running smoothly.

Construction demands are increasing, but hydraulics are evolving to meet the challenge! Manufacturers are focusing on innovations that deliver more power in smaller packages, extend equipment lifespan with eco-friendly materials, and reduce energy waste.

Cutting-edge control systems offer pinpoint accuracy, saving you time and fuel. Plus, integrated sensors and real-time monitoring alert you to potential problems before they cause costly downtime. Need to maneuver heavy loads in tight spaces?

New compact cylinders deliver the power you need without the bulk. These advancements are transforming the construction industry, helping you stay competitive and profitable.

Hydraulic cylinders are the unsung heroes of construction, providing the power and precision that underpin modern projects. From their humble beginnings to today’s cutting-edge applications, advancements in hydraulic cylinder design have fueled this continuous evolution.

These advances promise even greater efficiency, improved environmental sustainability, and further advancements in construction technology.

For construction professionals, understanding the latest hydraulic innovations is key. It’s essential for maximizing equipment performance, staying competitive, and making informed decisions about the future of your operations.

This includes not only using the best technology but also partnering with experts for expert maintenance and repairs.

Hydraulic cylinders are at the heart of your most powerful construction machinery. At Cylinders, Inc., we have over 30 years of experience expertly repairing and maintaining hydraulic systems. If you’re facing hydraulic challenges, contact us today!

We’ll provide reliable, tailored solutions that minimize downtime and keep your projects moving forward.

Explore articles on cylinder repair, maintenance best practices, and manufacturing insights.

To all who’ve been part of our journey this year,As we come to the close of another year, I would like to take a moment to thank you — our valued customers, partners, and colleagues — for the continued trust you place in Cylinders, Inc. Every day, our team has the privilege of supporting the businesses that keep America’s construction, industrial, and manufacturing sectors moving. It’s a responsibility we take seriously, and one we work hard to uphold with every repair, inspection, and consultation.

When winter takes hold across the United States, it’s more than just a dusting of white that greets commuters, it’s a full-scale challenge to keep roads open, fleets operational, and heavy machinery ready. Many U.S. states see between 40 and 70 inches of snow each year, with Vermont averaging about 89 inches annually and Michigan […]