Complete guide to winterizing construction equipment. Expert tips for protecting hydraulic systems and extending equipment life.

As colder months approach, the need to winterize your equipment is paramount for every construction company. Proper winterization not only enhances the lifespan of the machines and hydraulics but also reduces unnecessary costs associated with hydraulic repair services for construction. So, whether you’re operating in cold climates or experiencing infrequent snowfall, don’t overlook the need to prepare your construction equipment for winter. This is a critical step that ensures your equipment doesn’t freeze up when the mercury drops!

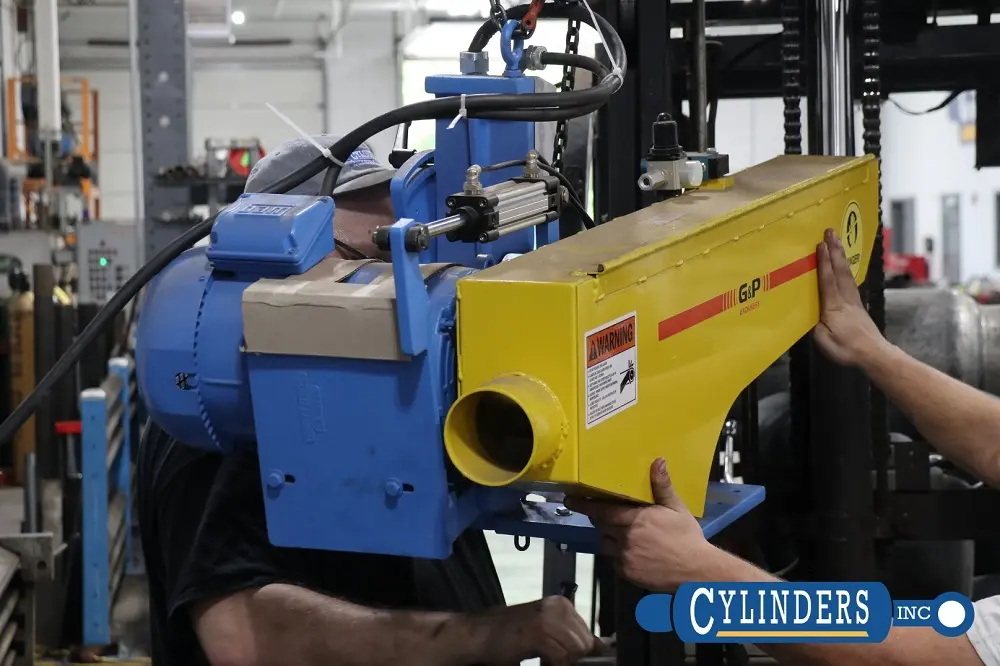

As colder weather approaches, our team at Cylinders, Inc. has outlined some helpful steps to keep your construction equipment running smoothly throughout the winter season.

Preparing your construction equipment for winter involves properly maintaining the oil and coolant systems. Firstly, check the oil viscosity and switch to a winter-grade oil if necessary to ensure smooth engine operation in colder temperatures. Don’t forget to drain and replace the coolant with a winter coolant mix to protect against freezing. These steps can help you can safeguard your equipment’s engine and hydraulic systems during the cold months of storage.

Preparing the hydraulics of your construction equipment for winter is important to ensure optimal performance in colder temperatures. Start by checking the hydraulic cylinders and hoses for any signs of hydraulic fluids leaks or damage. Be sure to inspect the hydraulic fluid levels and top them off as needed. It’s also key to allow the equipment to reach full operating temperature before you use it for heavy-duty work. By properly maintaining the hydraulic system, you can improve the efficiency and reliability of your heavy equipment during the freezing weather season.

When frigid temperatures arrive, worn parts on heavy equipment can fail and cause breakdowns. Before winter hits, thoroughly inspect your machinery for any components that need replacement. Look for damaged hoses, tires with inadequate tread, leaky gaskets, and bearings at the end of their lifespan. You’ll need to swap out worn parts for rugged cold-weather alternatives to help prevent equipment failure caused by freezing and wear during low-temperature operation.

As temperatures drop during winter, make sure to prepare the tires of your construction equipment. Start by conducting a visual inspection of the tires, looking for signs of wear or damage. Consider switching to winter tires with deeper treads for increased traction in snowy or icy conditions. The tires should be properly inflated according to manufacturer recommendations.

Another part of preventative maintenance is to address the issue of antifreeze. Ensure that the antifreeze levels are topped off and the mixture is appropriate for the freezing weather in your region. Additionally, don’t forget to check the diesel exhaust fluid (DEF) levels and replenish it if needed to ensure optimal performance of your heavy equipment during the colder months.

Winterizing construction equipment includes taking steps to protect the fuel system. Start by checking the fuel filters and replacing them if necessary to ensure proper fuel flow. Additionally, consider using dry nitrogen gas to fill the fuel tank to minimize condensation. For diesel engines, make sure the fuel is properly treated with an appropriate winter diesel additive. Taking these precautions will help maintain operating temperature and protect the fuel system throughout the winter.

Don’t forget to protect your batteries! You’ll need to prepare the batteries of your construction equipment for winter to keep the electrical components running smoothly. Start by cleaning the battery terminals to prevent corrosion and check the battery charge to ensure it’s fully charged before temperatures drop. Consider using a battery blanket or insulating material to provide extra protection from the cold and keep your equipment ready for operation during the winter season.

As colder weather approaches, make sure to replace fuel filters on your heavy equipment to prepare for operation. Start by checking and replacing the fuel filter to ensure proper fuel flow and prevent fuel line freeze-ups. Additionally, inspect and clean other filters, including air filters, hydraulic filters, and oil filters, to maintain efficient cold weather operation. By taking these steps, you can ensure that your heavy equipment is ready to tackle the challenges of winter conditions.

Getting conveyor systems ready for harsh winter operations is an important part of seasonal maintenance. Build-up and material residue can freeze on conveyor belts and pulleys, preventing proper operation. Before winter hits, thoroughly clean conveyors on your heavy equipment to remove debris. Check belts and rollers for wear and replace damaged parts. Cleaning your conveyor properly and maintaining it ahead of freezing temperatures will prevent downtime and keep your heavy machinery running efficiently all season long.

Now that you know how to winterize equipment, don’t forget about storage. This is crucial to protect it from the harsh elements and ensure its longevity. Proper storage practices can help prevent rust, corrosion, and other damage that can occur in cold and damp conditions.

Find a secure, covered area to shield your equipment from harsh elements such as snow, rain, and freezing temperatures. This will help prevent rust, corrosion, and other damage, to help your equipment remain in optimal condition until it’s time to use again.

To prevent rust damage while winterizing equipment, apply rust inhibitors and protective coatings to all exposed metal components. Engine parts like cylinders, pumps, and gears need extra defense against condensation and humidity during cold months in storage. You’ll want to properly treat your machinery with rust protection ensuring parts remain in quality condition when taking equipment out of seasonal hibernation.

During winter storage, protecting the electrical components of your equipment is essential for maintaining peak performance. Consider disconnecting the batteries or using a trickle charger to maintain battery health. Taking these precautions will safeguard the electrical system and ensure that your equipment is ready to perform its best when winter conditions subside.

When storing heavy equipment over the winter, it’s a good idea to set tracked machines on wooden planks and raise wheeled machines’ chassis to relieve static tire weight. This prevents sagging and distortion from gravity’s effects on stationary machines over time. Properly supporting equipment during winter downtime will help preserve structural integrity while not in use.

Keeping your construction equipment fully functional in winter conditions means you need to pay attention to various factors. We’ve outlined some additional tips to consider:

You can follow these additional tips and implement appropriate measures to optimize the performance and safety of your construction equipment during winter conditions.

Failing to winterize your construction equipment properly can be detrimental. If you don’t take the proper precautions, ice crystals can form within fuel lines and other components and cause blockages and fuel flow issues. Cold temperatures can also lead to cracked engine blocks or other damage, resulting in costly repairs. Additionally, if you start an engine in extremely cold weather without proper preparation, it can strain the equipment and lead to decreased performance or complete engine failure. By neglecting to winterize your heavy equipment, you risk significant damage, downtime, and increased maintenance expenses.

As our team has demonstrated throughout this article, the importance of winterizing your construction equipment cannot be overstated. Collaboration with a reliable local hydraulic cylinders repair company, such as Cylinders Inc., can be the key to navigating the challenges of the cold season. Equip your business for success this winter by taking action now: request an estimate and begin winterizing. This ensures that your company’s productivity remains unfazed by the freeze!

Explore articles on cylinder repair, maintenance best practices, and manufacturing insights.

To all who’ve been part of our journey this year,As we come to the close of another year, I would like to take a moment to thank you — our valued customers, partners, and colleagues — for the continued trust you place in Cylinders, Inc. Every day, our team has the privilege of supporting the businesses that keep America’s construction, industrial, and manufacturing sectors moving. It’s a responsibility we take seriously, and one we work hard to uphold with every repair, inspection, and consultation.

When winter takes hold across the United States, it’s more than just a dusting of white that greets commuters, it’s a full-scale challenge to keep roads open, fleets operational, and heavy machinery ready. Many U.S. states see between 40 and 70 inches of snow each year, with Vermont averaging about 89 inches annually and Michigan […]