Discover the importance of clean hydraulic fluid, different types of filters, and how to properly maintain your system for optimal performance.

As you know, maintaining your hydraulic filter ensures all impurities and contaminants are cleaned out for a longer-lasting system. With increased tolerances and pressure loads, contaminated hydraulic fluid can have increasingly harmful effects on equipment, making your maintenance all the more essential.

With the right hydraulic oil filters and filtration equipment, your system can run smoothly and last longer. When choosing the correct filters, and properly maintaining them, you can avoid the impact of contaminants on your system, avoiding damage to a well-running machine.

To better care for and maintain your hydraulic fluid filter and boost the longevity of your system, we are breaking down all you need to know about a hydraulic filtration system and how to maintain it. Let’s dive in!

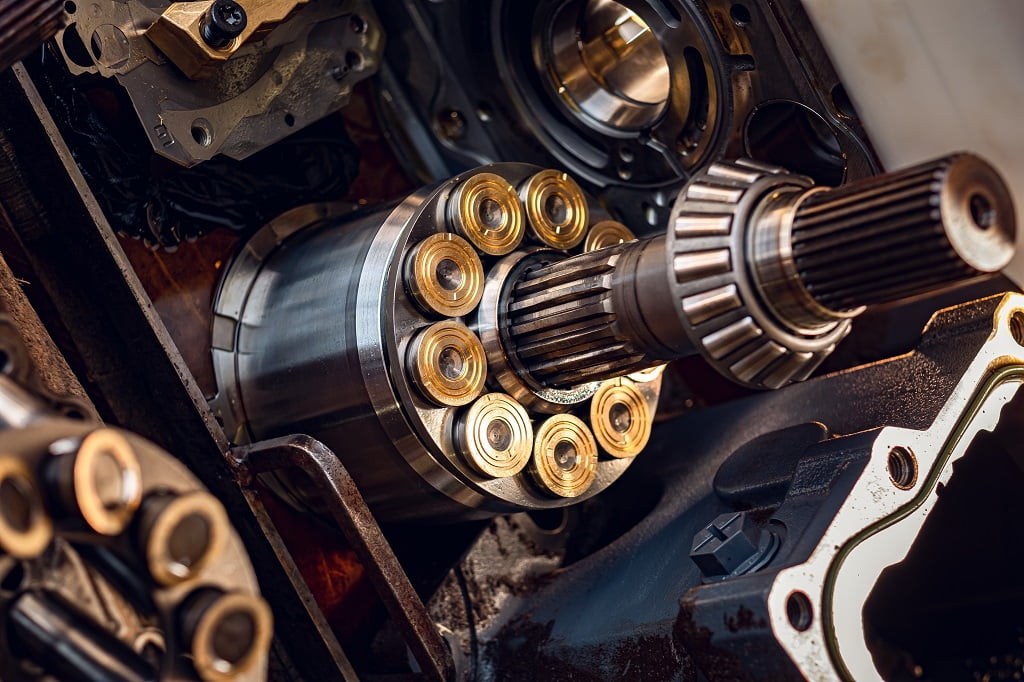

Hydraulic filters are used in hydraulic systems to keep contaminants from the fluid. To do so, the filtration system works by continuously removing the contaminants, ensuring the fluid remains clean for a well-running hydraulic tank filter and system.

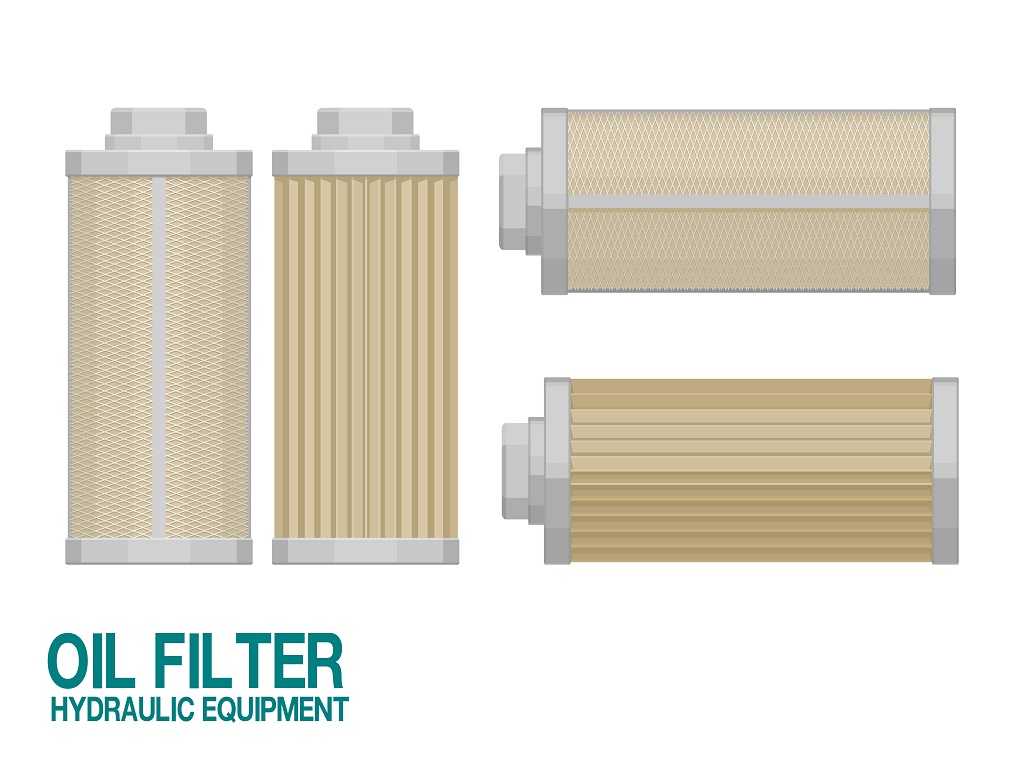

To purify and filter hydraulic fluid, different types of filters in hydraulic system units are used, ensuring each system is running well and clean. Some of the most common types of filters include:

A hydraulic filter is essential to ensuring a hydraulic system runs at optimal functioning capacity. With this in mind, there are a few different reasons hydraulic oil filters are implemented in a hydraulic system, including:

There are many ways contamination can impact the hydraulic fluid and ultimately the overall system. With the build-up of contamination, complications can get worse, leading to catastrophic impacts on your hydraulics. Some of the resulting damage includes:

A hydraulic filter is designed to remove contaminants from the system, but how do they get in there in the first place? Contaminants may enter the hydraulic system for various reasons, including:

Whether you need a hydraulic in-line filter or a hydraulic pump filter, there are some filtration options to choose from, each with a unique offering.

Each hydraulic filter component is designed for specific placement in the system. With this in mind, the filter you choose will depend on the positioning you need, in addition to a few other factors, including:

With the right hydraulic filter selection, you can aptly reduce the amount of dirt in your system, ensuring the system runs smoothly and efficiently.

Wondering if you need hydraulic pressure filters or hydraulic oil filters? Ensuring you have the right hydraulic filtration system is the first step to maintaining your system, but after that, it’s all about maintenance.

Once you have the right filtration system in place, ensure you follow the necessary maintenance steps, including:

A hydraulic filtration system is essential to a properly running hydraulic system, and with the right choice of filter and proper maintenance, you can avoid any unnecessary damage and replacement of your system, ensuring everything runs as it should. By getting ahead and promoting the longevity of your filters in a hydraulic system, you can not only ensure everything runs smoothly but reduce long-term maintenance and replacement costs.

Whether you have questions about the proper hydraulic filter for you or need a hydraulic cylinder repair company, our team at Cylinders, Inc. is here to help. To begin, request our service online today.

Explore articles on cylinder repair, maintenance best practices, and manufacturing insights.

To all who’ve been part of our journey this year,As we come to the close of another year, I would like to take a moment to thank you — our valued customers, partners, and colleagues — for the continued trust you place in Cylinders, Inc. Every day, our team has the privilege of supporting the businesses that keep America’s construction, industrial, and manufacturing sectors moving. It’s a responsibility we take seriously, and one we work hard to uphold with every repair, inspection, and consultation.

When winter takes hold across the United States, it’s more than just a dusting of white that greets commuters, it’s a full-scale challenge to keep roads open, fleets operational, and heavy machinery ready. Many U.S. states see between 40 and 70 inches of snow each year, with Vermont averaging about 89 inches annually and Michigan […]