Discover the hydraulic cylinder chrome plating in our blog post. Enhance performance and durability with this essential process for hydraulic cylinders.

Hydraulic cylinder chrome plating is a critical process for restoring the performance and durability of hydraulic cylinders. In this comprehensive blog post, follow along as our team at Cylinders, Inc. explores the definition, benefits, and types of hydraulic cylinder chroming.

Whether you’re looking to protect against corrosion, improve wear resistance, or enhance the aesthetic appeal of your hydraulic cylinders, understanding the intricacies of chrome plating is essential. Let’s delve into the various types of chrome plating available and provide insights on how to choose the right one for your needs. Read on to learn all about the purpose, techniques, and advantages of chrome plating for hydraulic cylinders.

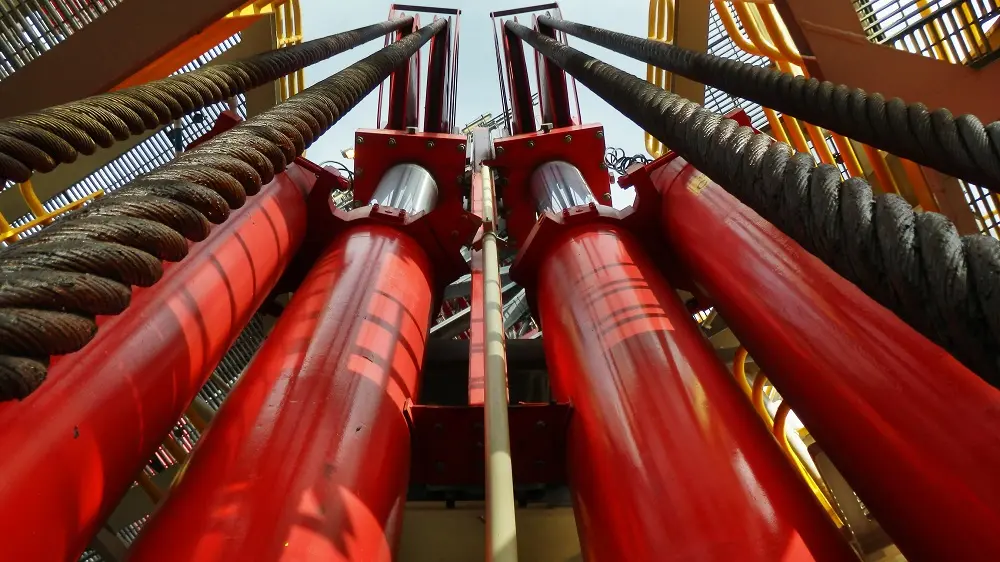

Let’s start with the basics. Hydraulic cylinder chrome plating is the process of electroplating a smooth, durable chrome coating onto hydraulic cylinder rods and other surfaces. It involves submerging components in a chrome bath and using electrical current to deposit a uniform chrome layer.

There’s a reason hydraulic cylinder chrome repair jobs have become so popular. With a host of benefits, and with a unique process to achieve, many are opting for this improvement to their hydraulic cylinders. Here are some reasons why this is so popular.

Electro-deposited chrome provides hydraulic components with an exceptionally hard surface. Through the chrome plating process, the components gain increased hardness without altering their inherent properties. This allows the components to retain their original strength and characteristics.

By combining exceptional hardness and low friction properties, hard chrome plating provides hydraulic cylinders with unparalleled resilience against abrasion and mechanical contact. The hard chrome surface forms a protective barrier that withstands the wear and tear caused by constant use and contact with other surfaces.

Hydraulic cylinder chroming is a process that offers exceptional oxidation resistance and improved resistance to both oxidizing and reducing agents. This makes it an ideal choice for applications where the cylinder is exposed to harsh environmental conditions or corrosive substances. The chrome plating creates a protective barrier that effectively guards against oxidation and helps the cylinders maintain optimal performance and durability over time.

As compared to steel, hard chrome has a super low coefficient of friction which allows a component to operate at a lower temperature. With this lower temperature during operation, many can postpone hydraulic cylinder repair until it’s necessary.

Hard chrome deposits on cylinder rods can be easily and conveniently removed using chemical strippers, without causing any damage to the underlying base material. This unique feature allows the chrome plating to be stripped and re-plated as needed. It also helps ensure the longevity and performance of the cylinder rods. By removing and reapplying the chrome plating, the structure beneath the surface remains intact and the integrity of the cylinder rod is preserved.

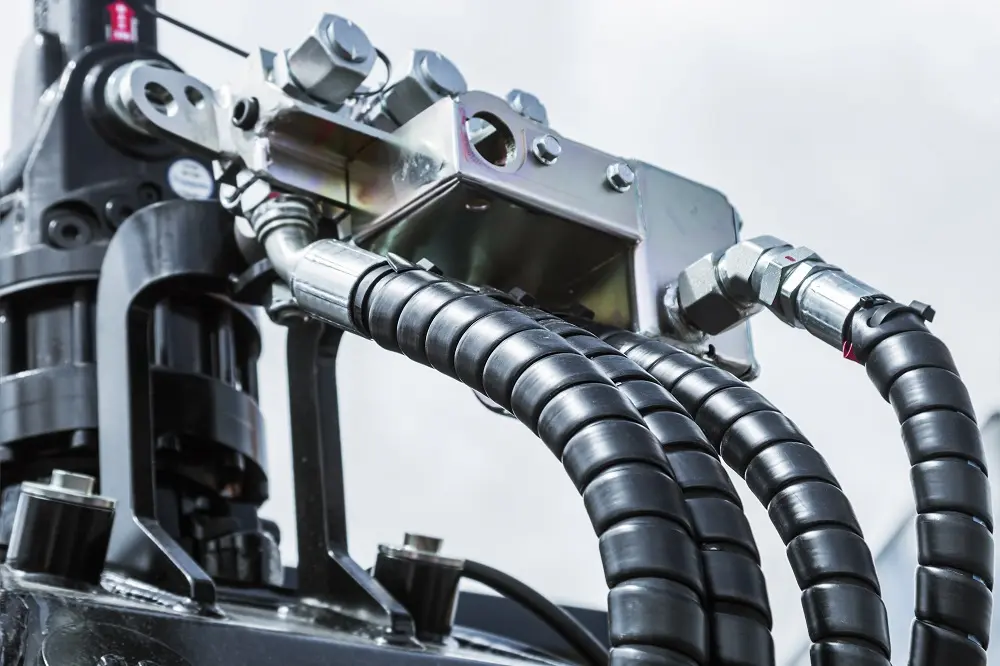

One of the advantages of hard chrome plating is its microcrack properties, which contribute to improved oil retention in the plated areas. These microcracks act as reservoirs, holding a thin layer of oil on the surface of the chrome, enhancing lubrication and reducing friction.

Now that we know all the benefits of chrome cylinder plating, it’s time to understand the process. A hydraulic cylinder chrome rod repair with plating takes time and care. You must understand the process to achieve the desired finish. To make things as easy as possible, we’re sharing a step-by-step guide to chrome plating.

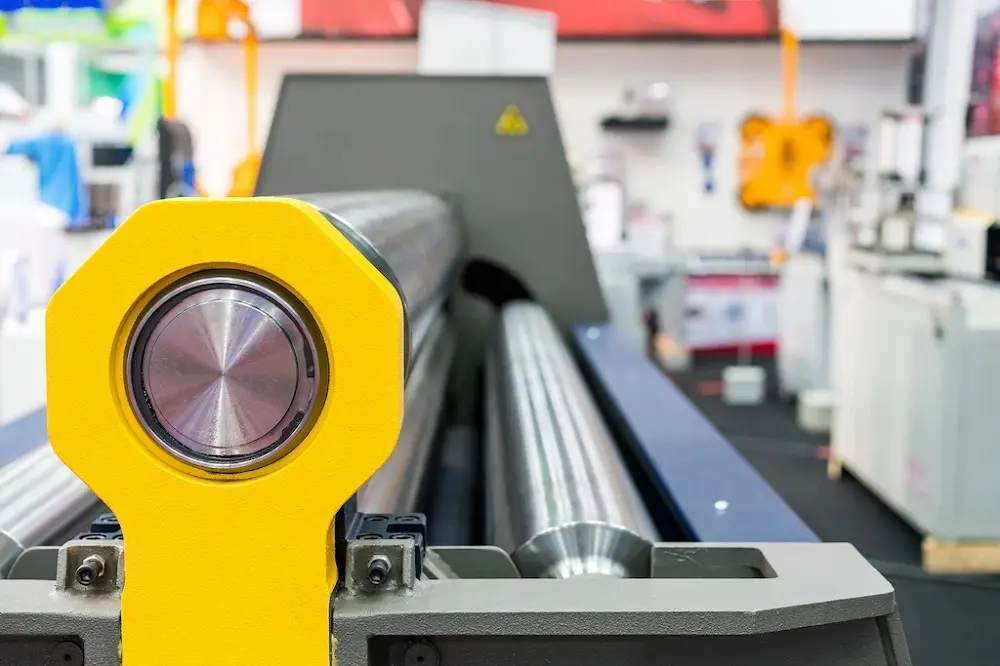

At the initial inspection, the rod is evaluated to determine its condition before chrome plating. This is where an inspector should look for any signs of corrosion, pitting, marring, damage, or cracking. Any damage will affect future steps of the re-chroming process.

Before the new chrome application, the old surface must be removed. However, to preserve the material beneath without reducing the diameter of the rod itself, this process must be done very carefully. There are two different approaches: grinding and stripping.

Now that the old chrome has been removed from the metal parts, it’s time to clean the surfaces. The rod should be cleaned and all debris and contaminants should be removed. If you don’t clean the rod first, anomalies could occur in the plating process, causing pitting or flaking, and ultimately limiting the lifespan of the newly plated chrome cylinder rod.

To plate the cylinder, it must be placed in a bath containing a solution of dissolved metal molecules. During this, electrodes are attached to the rod and a positive current is applied to the solution. This allows the metal particles in the solution to attract to the surface and adhere to it.

With heightened technical needs, a precise amount of current must be delivered at a steady rate, while the bath chemistry and temperature must remain the same throughout the entire plating process. Any interruptions or errors in the power and temperature will result in a poor chroming job and cause the chrome cylinder rod to require more refinishing repair.

Now that a fresh layer of chrome is on the rod, it’s time to finish it up. This involves two steps: post-grinding and linishing.

Before wrapping up the cylinder, it’s time for an inspection. A professional has a trained eye and can carefully account for the thickness and roughness of the rod to determine the quality.

The final step of the hydraulic cylinder rod chrome plating process is wrapping. During this step, the rod is securely wrapped in cardboard and protective plastic to safeguard the chrome while it’s transported back to where it belongs.

There’s more than one type of chrome surface to consider. A few different types of chrome plating can be used on hydraulic cylinders, depending on the application and required durability.

The attractive, reflective finish of engineering chrome plating makes it popular. Still, its use goes beyond simply providing an aesthetically pleasing look. Chrome plating also serves a practical purpose as a protective layer so it’s often employed in cylinder rods, piston rings, gun bores, and railers.

Decorative chrome is a combination of nickel and copper beneath a thin chromium coating, which creates a glossy and reflective surface and provides protection against corrosion. It not only enhances the aesthetics of the object but also provides excellent corrosion resistance, making it a popular choice for both functional and decorative purposes. The versatility and durability of decorative chrome plating make it a preferred option for achieving a sleek and stylish look in various industries.

Black chrome plating is a specialized process that adds a stylish and distinctive touch to various objects through a unique black finish. This type of plating is commonly used for decorative purposes, creating a sleek and modern aesthetic. The black chrome plating process involves depositing a layer of black chromium onto the surface, resulting in a reflective black coating.

Flash chrome plating is ideal for applications exposed to light wear, as it offers good corrosion resistance despite its thin layer. This type of plating is employed as a decorative finish and for parts that require rust and corrosion resistance.

Hexavalent chrome plating, also known as hexavalent chromium plating, is a traditional plating method that utilizes a solution containing compounds of hexavalent chromium. This process offers excellent corrosion resistance, wear resistance, and aesthetic appeal.

Thin dense chrome plating improves metal surfaces’ corrosion and wear resistance. Its electrolyte solution is made of chromium and sulfuric acid and an anode of pure chromium metal, which creates a very thin, dense coating of chromium on the surface of the metal that is highly resistant to corrosion and wear.

Hard chrome plating is a process that coats metal parts with a hard, wear-resistant layer. It’s commonly used in the aerospace, automotive, and engineering industries to protect components from corrosion, wear, and abrasion. It can also increase the surface hardness of other metals, such as stainless steel.

The longevity of your equipment’s chrome plating largely depends on its condition and the environment in which you use it. Generally, re-chroming services should be performed every couple of decades in non-wear situations.

The need for re-chroming services is usually decided by the thickness of the chrome layer, how often maintenance and care are provided, and the quality of the chrome plating materials.

Chrome plating provides a nice finish and protects your equipment from wear, impact, and corrosion. If you see any signs of damage or rust, you may need re-chroming services sooner rather than later.

The process of hydraulic cylinder chroming takes special attention and care, ensuring that the newly-plated chrome cylinder has the correct thickness and roughness for it to function properly in your machinery. While this takes special care and attention, it’s well worth the effort to extend the lifetime of your chrome cylinder rod.

To have an expert team handle your hydraulic cylinder chrome repair, Cylinders, Inc. is here to assist. As an expert hydraulic cylinder re-chroming company, our team will work hard to ensure your cylinder rod is expertly repaired for years of use ahead. To begin the process of working with our friendly and experienced team, contact us online today.

Explore articles on cylinder repair, maintenance best practices, and manufacturing insights.

To all who’ve been part of our journey this year,As we come to the close of another year, I would like to take a moment to thank you — our valued customers, partners, and colleagues — for the continued trust you place in Cylinders, Inc. Every day, our team has the privilege of supporting the businesses that keep America’s construction, industrial, and manufacturing sectors moving. It’s a responsibility we take seriously, and one we work hard to uphold with every repair, inspection, and consultation.

When winter takes hold across the United States, it’s more than just a dusting of white that greets commuters, it’s a full-scale challenge to keep roads open, fleets operational, and heavy machinery ready. Many U.S. states see between 40 and 70 inches of snow each year, with Vermont averaging about 89 inches annually and Michigan […]