Learn the best practices for synchronizing hydraulic cylinders including installation, calibration, troubleshooting common errors, and maintenance tips.

Proper synchronization of double-acting hydraulic cylinders is critical to ensure a smooth and efficient machine operation. At Cylinders, Inc, we specialize in double-acting hydraulic cylinder repair and understand the importance of having cylinders move in unison. When cylinders are out of sync, it leads to inconsistent motion, excessive wear, and mechanical issues.

By correctly synchronizing your hydraulic cylinders, you can maximize performance, avoid downtime, and extend the lifespan of your equipment. Our knowledgeable team has put together this article to help you understand the synchronization process and the benefits of having expertly synchronized cylinders for optimal functioning.

Hydraulic systems that utilize multiple cylinders require precise synchronization between the cylinders to function properly. Without proper synchronization, the cylinders will move sporadically and out of sequence rather than in tandem. Expert synchronization aligns the cylinders so they operate in perfect coordination, which enables smooth and efficient system operation. Technicians use various methods to synchronize hydraulic cylinders such as flow dividers, counterbalance valves, and flow control valves.

Hydraulic valves and controls play an important role in enabling cylinder synchronization within a hydraulic system. Components like directional control valves actively regulate and direct the flow of hydraulic fluid to synchronize cylinder movements. Flow control valves manage the speed and rate of fluid flow to ensure smooth, controlled motion. Counterbalance valves are also key for controlled synchronization by compensating for external forces on the cylinders. Proper valve setup, control, and adjustment are pivotal factors in effectively synchronizing multiple hydraulic cylinders for optimum performance.

The proper preparation ensures hydraulic systems are ready for synchronization.

As you can imagine, synchronizing hydraulic cylinders requires careful preparation. Technicians need to consult OEM procedures where available, always wear proper PPE and follow safety protocols. Cylinders, valves, pumps, and lines are precision machined and rated for the expected pressures. Hydraulic fluid and filters are checked. Rods, seals, and mounts are inspected for wear and leaks. Venting safely releases trapped air. Verifying all components are in good working order before attempting to synchronize the system prevents failures or accidents.

Next comes inspection. Proper hydraulic cylinder maintenance increases the chances of successful synchronization. Technicians will inspect cylinder rods, seals, chambers, and bores for signs of damage or wear, and seals and wipers will be replaced to prevent leaks. Cylinder mounts are checked for looseness while contamination is flushed from the system. Slave cylinders are tuned to match the flow divider or control valve. It’s ideal to perform thorough cylinder inspection and maintenance before attempting synchronization to prevent malfunctions or leaks.

Is synchronization truly needed? This determination can help prevent over-engineering. Consider the loads, lifting heights, cycle rates, and position accuracy required. Weigh factors like cost, complexity, and maintenance. Another consideration is that synchronization may only be critical in a portion of the cycle. Look for binding or wear that causes unsynchronized motion. If needed, you can discuss needs with cylinder and valve suppliers. Carefully evaluating the application identifies where and how synchronization benefits performance, safety, and efficiency.

Synchronizing multiple hydraulic cylinders can present some unique challenges:

Various techniques enable hydraulic cylinders to move in precise synchronized motion.

Mechanical linkages physically couple the hydraulic cylinders to synchronize their motion. Linkages such as bars, gears, or pulley systems interconnect two or more cylinders. As one cylinder extends or retracts, it mechanically drives the attached cylinders to move simultaneously. Mechanical linkages offer a simple, cost-effective way to synchronize small numbers of hydraulic cylinders in applications like lifting platforms or bucket excavators.

Active load sensing is an advanced yet simple solution for synchronizing hydraulic cylinders. It utilizes a closed-loop hydraulic circuit with pressure sensors on the cylinders. This allows the system to actively balance the pressures by regulating pump flow. Continuous adjustment allows the cylinders to remain synchronized. Active load sensing is a cost-effective, responsive way to achieve precision cylinder synchronization without complex electronics. For most applications, it’s an ideal advanced technique for this critical synchronizing task.

Electronic control systems use sensors, valves, and controllers to actively synchronize hydraulic cylinders. By monitoring cylinder positions and loads, the control system can respond in real time to ensure equal flow and pressure to each cylinder. This closed-loop feedback control continually adjusts to maintain precise synchronization, even when load conditions are changing. Electronic control provides adaptive, intelligent cylinder synchronization for demanding applications.

Proportional valves enable accurate flow control for synchronizing hydraulic cylinders. By proportionally regulating oil flow to each cylinder, the valves can divide flow evenly. As loads change, proportional valves dynamically adjust oil flow to match cylinder pressure demands, keeping the cylinders synchronized. Proportional valve control systems provide responsive, adaptive cylinder synchronization without complex electronics. This simple, cost-effective method works well for many applications.

Synchronizing hydraulic cylinders follow a methodical sequence for peak accuracy and performance.

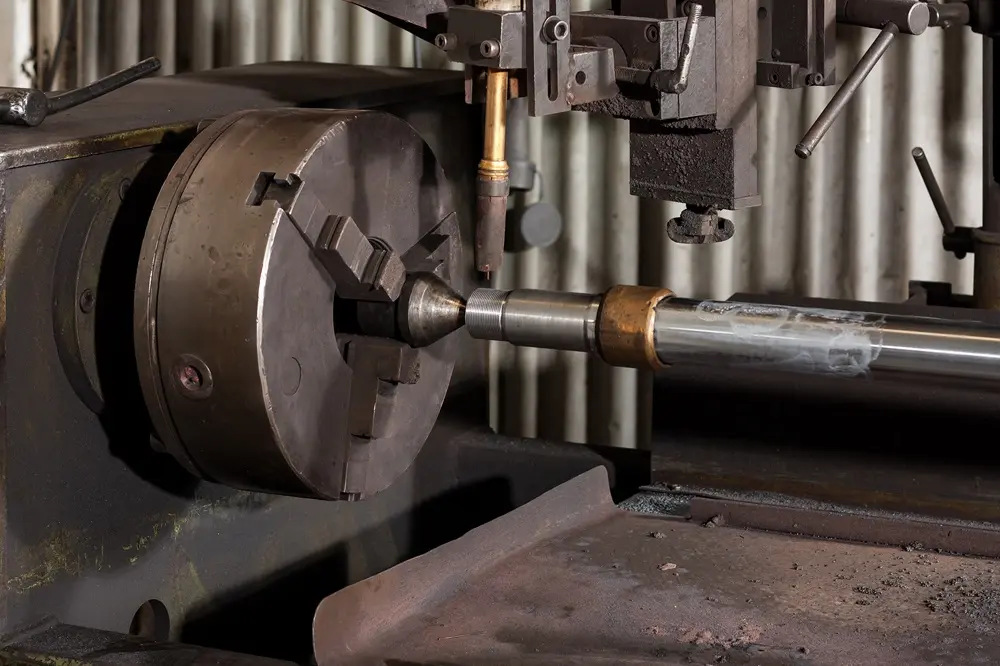

The first step in synchronizing hydraulic cylinders is proper system setup. Cylinders must be installed and linked according to the application. Required valves, pumps, reservoirs, and sensors are mounted and connected via hydraulic lines. The right hydraulic fluid is selected and added to the specifications and bleeding removes air pockets. This critical preparation ensures cylinders have the surrounding infrastructure for smooth pump actuation and synchronization before calibration and testing. If you take the time to methodically set up the hydraulics, it can prevent issues down the line.

Once the hydraulic system is installed, calibration tuning achieves synchronization. Cylinders are set to zero positions as a baseline point and sensors are calibrated to properly track cylinder extension. Valves are adjusted for equal division of flow rates. Calibration verifies cylinders will move in unison through full stroke ranges before connecting loads. Taking the time to fine-tune calibrations prevents synchronization issues when the system is operational under real loads.

After calibration, hydraulic cylinder synchronization systems require testing and fine-tuning. Cylinders are run through full motion cycles while monitoring for synchronization. Control parameters are adjusted to fix any lagging or leading cylinders. Pressure, flow rate, and response settings are tweaked to perfect synchronization. Iterative testing refines the system until cylinders move precisely in unison for the intended loads and cycles. Careful testing and tuning ensure optimal real-world synchronization performance.

Even with proper setup, calibration, and testing, issues can occur with hydraulic cylinder synchronization. Technicians methodically troubleshoot by checking position sensor accuracy, hose pressures, flow rates, and valve response. Contamination, hydraulic leakages, or mechanical binding are other common problems. Isolating the out-of-sync cylinder and components points to the root cause and addressing synchronization problems as they arise prevents damage from position shifts or uneven lift.

Achieving precise hydraulic cylinder synchronization requires more than just installation and calibration. Additional factors can also significantly impact accuracy.

When synchronizing hydraulic cylinders, the cylinders must be properly sized and matched to enable precise synchronized movement. Differences in cylinder bore, rod diameter, stroke length, or performance can reduce synchronization accuracy. Identical cylinder size and stroke capabilities allow for smooth, even extension and retraction. Furthermore, cylinders must be able to handle the system pressure and flow rates without binding or lagging. Proper sizing, selection, and matching of cylinders is crucial for precise control and synchronization.

Achieving accurate synchronization requires properly regulating hydraulic fluid flow and pressure to the cylinders. The flow must be evenly divided using valves or other distribution methods. The system should provide adequate flow rates and pressure from pumps and hydraulic oil to avoid lag or binding. Continuous monitoring and control of pressure allows on-the-fly adjustments to maintain synchronization. From distribution to real-time modulation, managing fluid flow and pressure is essential for precise and responsive control when synchronizing hydraulic cylinders.

Load imbalances and over-travel can disrupt synchronized cylinder movements. If cylinders are lifting uneven loads, flow and pressure differences will push one cylinder ahead. Over-travel and extending further than needed also gets cylinders out of sync. Compensation methods like flow control valves or counterbalance valves help prevent these issues. In addition, careful system design and monitoring help identify and address potential synchronization problems from load imbalances or over-travel when synchronizing hydraulic cylinders.

Synchronizing hydraulic cylinders is critical for optimized system performance, safety, and efficiency. We encourage operators to follow the best practices for installation, calibration, troubleshooting, and maintenance to achieve precise synchronized cylinder motion. At Cylinders, Inc., we’re a top double-acting cylinder rebuilder that understands the importance of proper synchronization. In addition, if one of your synchronized cylinders is beyond economical repair, Cylinders can re-manufacture a matching cylinder to assure synchronized movements are maintained.

By researching synchronization methods, inspecting your hydraulic components, and addressing errors proactively, you can advance your hydraulic system to new levels of productivity. Don’t let cylinder synchronization issues hold you back – take action now and experience the benefits of efficient hydraulic cylinder operation. Contact us today to schedule your repair and unlock the full potential of your hydraulic system.

Explore articles on cylinder repair, maintenance best practices, and manufacturing insights.

To all who’ve been part of our journey this year,As we come to the close of another year, I would like to take a moment to thank you — our valued customers, partners, and colleagues — for the continued trust you place in Cylinders, Inc. Every day, our team has the privilege of supporting the businesses that keep America’s construction, industrial, and manufacturing sectors moving. It’s a responsibility we take seriously, and one we work hard to uphold with every repair, inspection, and consultation.

When winter takes hold across the United States, it’s more than just a dusting of white that greets commuters, it’s a full-scale challenge to keep roads open, fleets operational, and heavy machinery ready. Many U.S. states see between 40 and 70 inches of snow each year, with Vermont averaging about 89 inches annually and Michigan […]